ELIMINATE and CONTROL:

- Negative Air Pressure in Plants / Factories.

- Air Contaminants Controlled With Less Exhaust Air.

EnergyMaster® strategically delivers make-up air throughout your plant in relation to the contamination source. Therefore, the amount of air exhausted can be significantly reduced while maintaining clean air conditions. For example, in northern Ohio and southern Michigan, each 1000 cubic feet of exhaust air reduced, provides a savings of 25,000 to 50,000 BTU’s per hour. - Carbon Monoxide, Welding Smoke, Fumes, Mist, Dust, Odor —

- EnergyMaster® controls or replaces plant air contaminants while exhausting them outside. Low velocity fresh air remains circulating throughout the workspace. The most direct method is utilized so a minimal amount of CFM is used to control these air contaminants

- Dead Air Spots

- Overheated Areas (Eliminate/Relocate Heat).

- Inexpensively moves excessive objectionable heat, to distant areas that can use it.

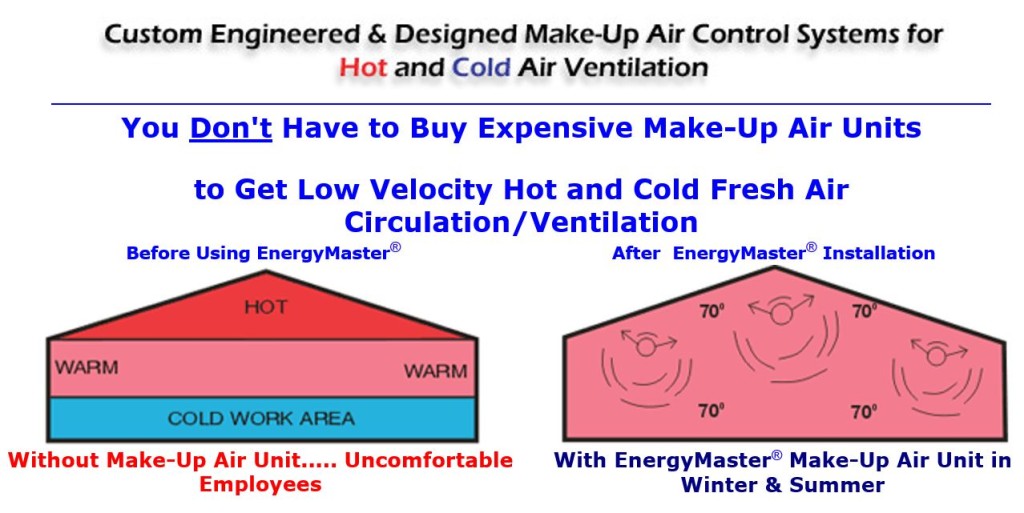

- Cold, Drafty Floors

- Indoor Air Quality / Ventilation Problems

RESULTING IN:

- Return On Investment

- More Comfortable and Productive Employees

- Helps Meet Clean Air Regulations Inexpensively.

When EnergyMaster® evenly distributes outside make-up air throughout a building in conjunction with an adequate exhaust system, it uses the minimum amount of outside make-up air possible to reduce the air contamination concentration (PPM) to an acceptable level. - EnergyMaster® brings outside make-up air into a building through its unique distribution duct system. It uses up to 100% of the stratified heat (heat loss) at the ceiling which is otherwise wasted when it is lost through the roof.

Click Here to See How EnergyMaster® Works

Click Here to See How SeasonMaster® Works